A Cut Above the Rest

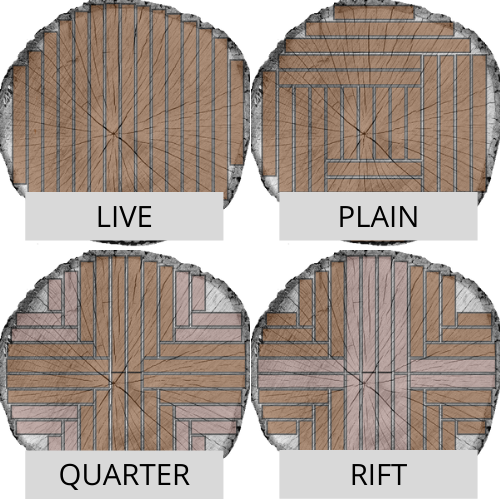

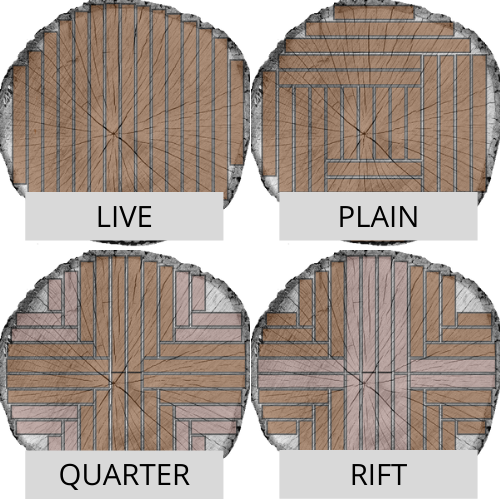

When it comes to hardwood flooring, one of the options you may be faced with is whether you want your planks to be live sawn, plain sawn, quarter sawn, or rift sawn. Each type of cut has its unique qualities. However, unless they work in the hardwood flooring industry, most people are not familiar with these terms or the differences. We want to introduce you to these different types of cuts and explain how they are different and what kind of flooring they are best used for.

So, as mentioned above, there are four basic ways of cutting hardwood flooring: live, plain, quarter, and rift.

As you can see from the diagram, grain patterns, board width, number of boards produced, and the amount of waste will be different between each type of cut.

Let’s take a deeper look at each kind:

Live Sawn

This is the oldest and most traditional way to cut a log into planks. You can trace this method of cutting back to some of the earliest shipbuilding techniques. It is also considered one of the most efficient ways to cut a log, being faster and resulting in less waste since the logs are cut directly through without having to be turned. Because the logs are cut straight through, there is a full range of grain variation, resulting in a truly unique grain pattern for each board. Additionally, this type of cut will produce planks that have both the darker heartwood and the lighter sapwood, resulting in a breathtaking contrast within each board.

Plain Sawn

This is the most common way of cutting a log, so it is what is more readily available when shopping for hardwood flooring. Because the log is cut so that there is no more than a 35-degree angle from the growth ring, the grain pattern ends up as what we refer to as “cathedral style.” This aesthetically pleasing pattern is what most people envision when they think about hardwood flooring. When it comes to waste, this way of cutting wood only produces slightly more waste than live sawn, so it is another good option in that regard.

Quarter Sawn

Being a more expensive way of cutting a log, this type of cut is generally used in furniture and hardwood flooring with thinner planks. As the name suggests, the log is cut lengthwise into quarters, producing four wedges. Because the wedges are cut at a right angle set to the center of the log, the boards will have a straighter grain pattern, generally be more water resistant, and produce more waste than plain sawn.

Rift Sawn

This type of cut is the most expensive and produces the most waste. Therefore, it is one of the least common cuts on the market. It is similar to quarter sawn, as you can see from the diagram, but wider boards are taken from the center of the tree. This results in grain patterns that are straight and tight, which makes the wood more stable, being more resistant to changes in temperature and humidity. If humidity is a concern in your area, rift sawn is a good option for you.

While each type of cut has pros and cons, we generally recommend live sawn when it comes to wide plank flooring. This is particularly true if you are installing white oak. Live sawn white oak is truly beautiful, complementing both a modern and rustic look and feel. Take a look at some of our live sawn white oak projects below to see how this type of cut can add to the aesthetic appeal of your home or business: