What Does "Live Sawn" Mean?

If you have been following us on social media, you have probably seen posts that include the world “live sawn.” Unless you are in the industry or have done your own research before buying flooring, you might not know what that means. We thought we would take a few minutes to explain what it means as it pertains to hardwood flooring and how it compares to other methods like “plain sawn,” “rift sawn,” and “quarter sawn.”

First of all, everyone knows that hardwood floors come from trees. The type of tree depends on the particular look and feel you want for your floor, the level of hardness you need (think Janka scale rating), environmental factors, and cost. No matter what kind of tree you use, it has to be harvested. This involves cutting down the tree and removing the branches. Then it ends up on a truck and taken to a lumber mill where it is processed and cut accordingly. What people do not realize is that how the tree is sawn makes a huge difference in the look and stability of the wood, especially when it comes to flooring.

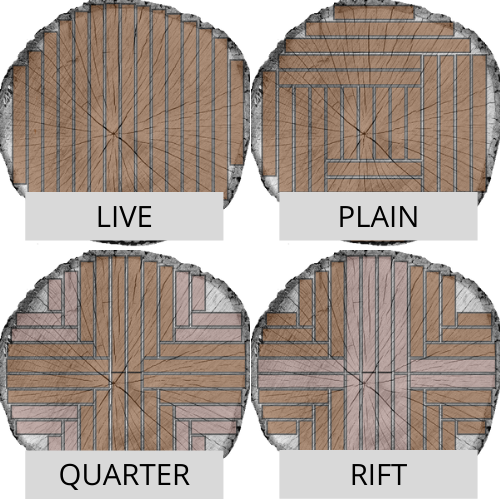

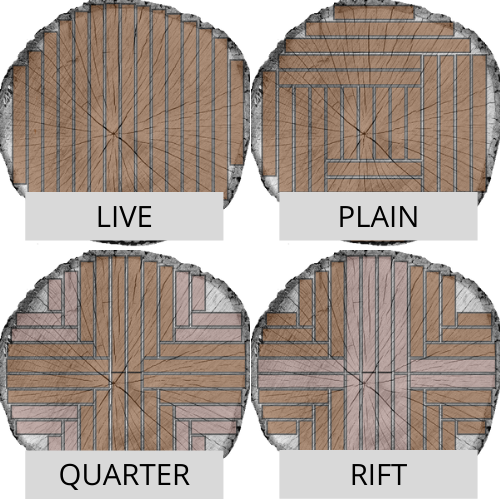

There are four basic ways hardwood flooring is cut, each with pros and cons. These include live sawn, plain sawn, quarter sawn, and rift sawn.

Let’s break each type down:

Live Sawn

This is one of the oldest ways to cut a log, dating back to early shipbuilding techniques! It is also the most efficient way. With live sawn, the logs are cut directly through without turning (as opposed to the other types), creating the least amount of waste. By cutting straight through the log, the planks can have a full range of grain variation. It also provides for planks to include both the heartwood and the sapwood, creating a stunning contrast within the board itself.

Plain Sawn

Using slightly more waste than live sawn, this method of cutting a log is one of the most common. The log is cut so that there is usually no more than 35 degrees within the angle of the growth ring. This produces the cathedral style grain pattern that is common and aesthetically pleasing in hardwood flooring.

Quarter Sawn

This type of cut produces more waste and is more expensive than plain sawn. It is generally used in furniture and thinner planked wood floors. The process consists of quartering the log lengthwise, produces wedges that are set at right angles to the center of the log. Planks cut with this method usually have a straighter grain and are generally more water resistant.

Rift Sawn

Flooring that is cut using this method is generally the most expensive and produces the most waste. Because it is so expensive, it is the least common. Rift sawn is similar to quarter sawn, but the boards are taken from further outside the log. Because of this, the boards are usually thinner and the grain is very straight and tight. This type of grain makes the wood more stable, minimizing the expansion and contraction common in hardwood flooring.

Out of all the different methods, we prefer live sawn, especially for wide plank white oak installations. Live sawn white oak has a true rustic charm, yet can also complement a more modern style. It provides a unique look and feel to your home or business that you are sure to enjoy for years to come.

Take a look at some of these live sawn wide plank white oak floors we have recently installed – you can certainly see the appeal!